Cement Plant Scheklingen

As part of the modernization of the Scheklingen cement plant, HeidelbergCement AG had the new WT05 kiln line built, which replaces the existing L03 Lepol kiln and the WT04 heat exchanger kiln. The efficient and modern kiln system has significantly lower pollutant and C02 emissions with a constant daily production of around 5000 t of cement clinker.

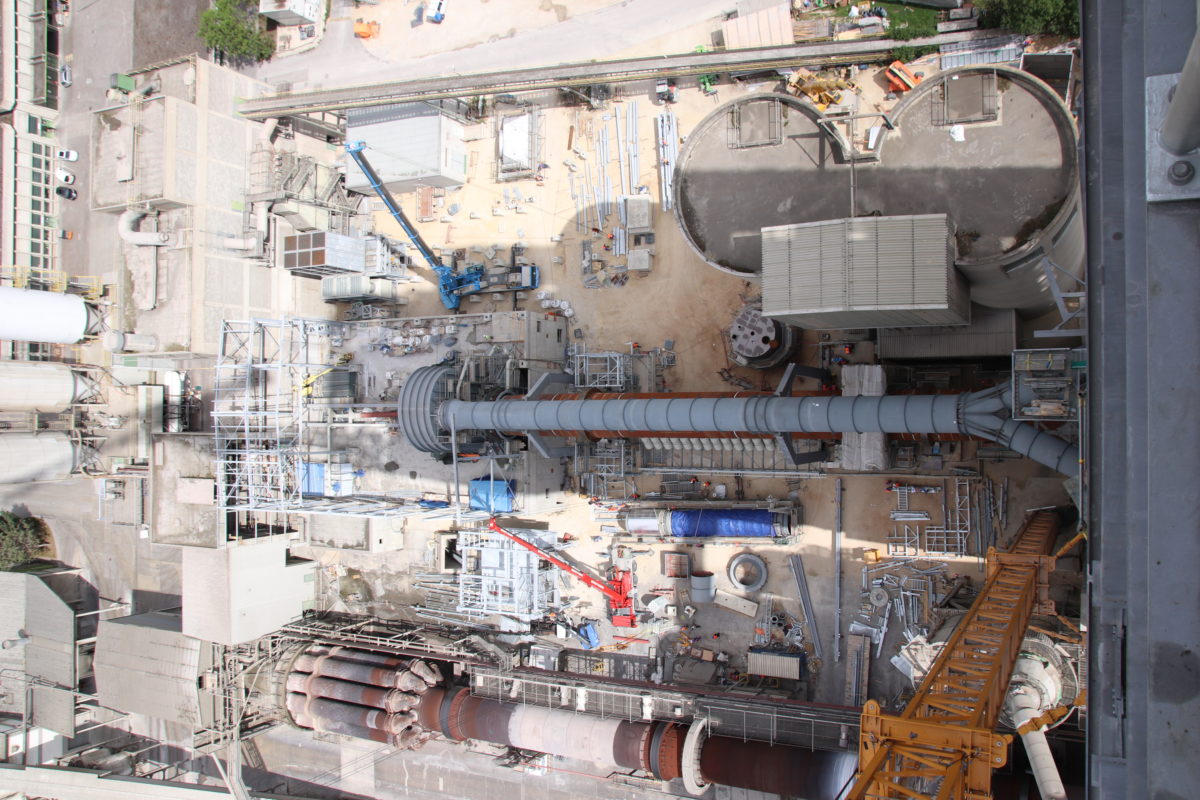

The new kiln line consists of numerous individual structures, including the evaporative cooler, the heat exchanger, the rotary kiln foundations, a clinker cooler building and various piping supports. Furthermore, a secondary fuel storage hall with conveyor bridges was built in the factory. Due to the proximity to the city of Schelklingen, special emphasis is placed on sound insulation.

The heat exchanger is the tallest and largest building to be built as part of the modernization. The tower is divided into a solid substructure and an attached steel structure. The axis dimensions are approx. 20.4 x 22.4 m in the floor plan and the total height is approx. 145 m. A special feature of the steel construction is the design with only four corner supports, which means that one has to be spanned with self-supporting steel beams in levels over 20 m have a maximum height of 3.30 m.

Our service includes structural testing (testing engineer Dipl.-Ing. Dieter Lippold).